If one of your machines were to stop right now, you would like to know about it. If you know it has stopped, you can do something about it. Our live monitoring system is able to monitor production in real time and help deliver constantly high performance data. Our simple to operate systems help our customers achieve fast results.

Connected to each machine, Our system is able to monitor production in real time and deliver live, up to date information to any part of your factory.

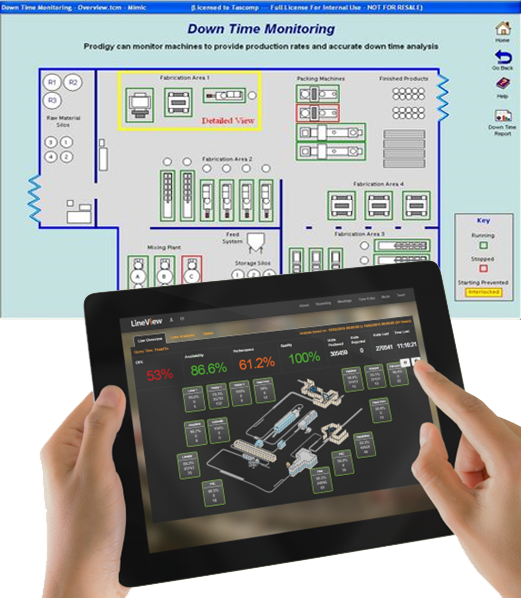

The current status of each machine can be seen at a glance. Key performance figures such as scrap rate, down time, efficiency, utilization and set-up time are displayed on fully configurable mimic diagrams, details pages and summary pages through familiar Windows based software.

Operators can also interact with the system through easy to use keypads located at each machine on the shop floor.

All data collected by the monitoring system is recorded in the our archive database. As well as being available to the our reporting module, the archive database can be integrated through industry standard software such as Microsoft Excel or Access.

We provide an easy to use and intuitive scheduling module. Jobs can be input manually or downloaded automatically from your existing manufacturing system.

The job schedule view gives details of each job enabling operators on the shop floor to prepare for up-coming tool changes.

The chart view provides a graphical visualization of machine loading and capacity utilization. Rescheduling is easily achieved through a simple drag and drop operation. Jobs on the chart can be highlighted for various reasons. For example, to identify tool changes, late jobs or resource clashes etc.

The plan takes your shift pattern into account, as well as any planned maintenance, overtime or shutdowns. Furthermore, each individual job can be forward scheduled or backward scheduled to highlight spare capacity.

The reporting module draws on the data collected by the monitoring module. Reports can be configured for any selected period with many different key performance figures such as:

Reports can be generated for each shift, day, week, month, year or job. Reporting is available by machine, tool, product or workgroup.

Reports can be generated on demand at any computer configured as an our terminal, or programmed to automatically print at the end of each shift, day, month etc.