As custom machine builders, We understands that creating a machine from concept stage requires extensive knowledge of machine components capabilities. PT. SINDO Seiki Aditama experienced design/build firm that is skilled at proving functionality at critical points in the machine development process. We complete the following steps for every machine:

Every project starts with a base level concept with varying degrees of detail. From concept to fully developed machine spec, we take your concept and make it a reality. At this stage of the process our machine builders help you:

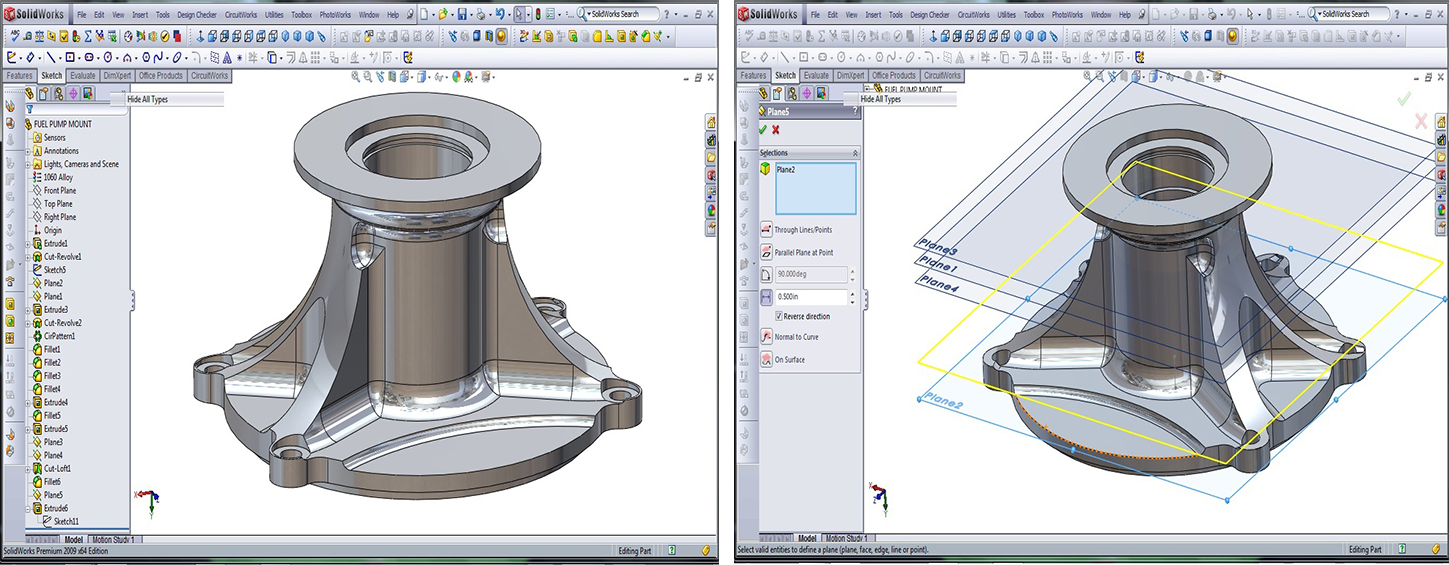

This stage will be combine all of information and plot into detail of the machine design, by integrating the details that constitute a final machine design. Included in this phase are:

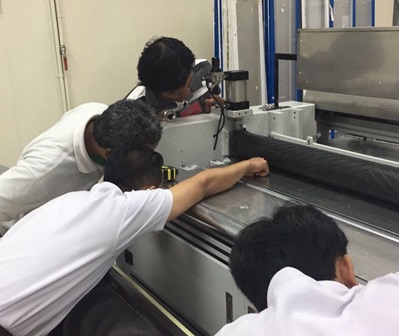

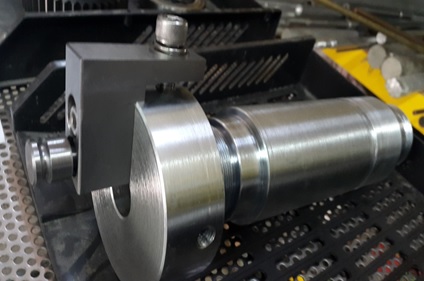

Your machine will then be fabricated by our skilled machinist at our in-house workshop. This stage includes:

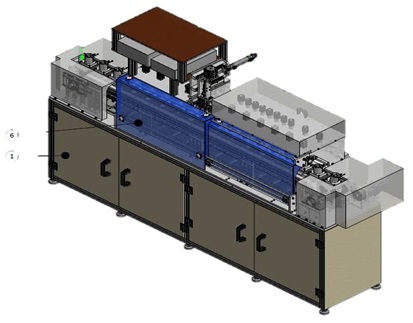

All parts fabrication and standard parts will be than assembly, wiring and programing. Our engineer and machine builder who worked with you on the step by step flow of the project will ensure that the machine are base on the specification. In the machine assembly phase of your project our team will:

As the custom machine builder, the machines that leave our facility are fully tested while operating at required specifications. We welcome our clients to our facility to be an integral part of this process. Our machine review process includes:

Our expertise will support to perform the installation, commissioning and provide training to your team on how to use and maintain the machine, this phase are included: